Oil Pressure Sender

Since my temperature sender was readin low when installed with a T connector in the side of the block, I thought I better move it to the oil drain plate. This is a good idea, and if CB Performance had their act together they'd carry the VDO kit made for this purpose.

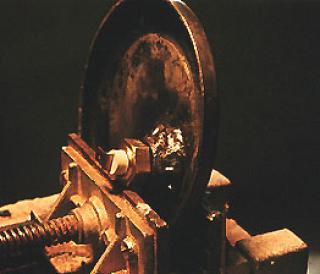

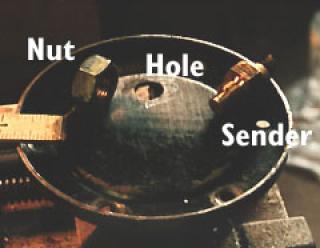

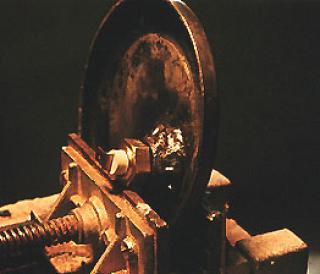

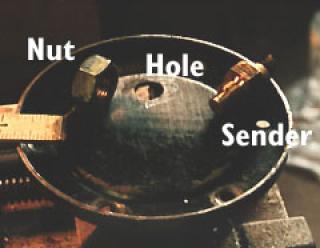

Not having the kit, and being adventurous, I decided to weld a big nut to my oil drain plate, off center so that the temp sender wouldn't hit the oil return screen. I carefully (well, pretty careful anyway) measured with the screen and sender and the nut. You can see where I drilled my hole. I lined up the bolt holes so that the send would be at the rear of the drain plate. I think it's 1/2 inch (12.7 mm) diameter. I then used an inexpensive arc welder to weld the nut to the oil drain plate. It worked! I had to make about a dozen passes with the welder as this was only the third weld I ever made. You can see in the lower photo that the weld looks like silver bubble gum. However, ugly, it's solid.

Clearly, I'll need a skid plate to protect the temp sender. Remember, I'm building a Baja here. Even on the street, something to protect the sender would be good. I though about just welding a little fin in front of the sender.

This worked just great, sort of. After everything was put together, I discovered that my temp gauge still hardly registered. I was guessing either the gauge or sender was bad, but I've replaced both.

Apparently my oil sump plate is not well grounded. In a few weeks (i.e. March 2001), I'll try this again, and carefully ground the oil sump plate.

After installing the temp sending in the oil drain plate, it always read low. My engine could be almost smoking hot, and the gauge still read 140 degrees F. So, I installed a T like the one on the left in the oil line coming out of my oil pump. This read a correct temp: about 200 when the engine was warm.

Note one important lesson: the photo on the left shows smooth connectors. These were really, really bad. They are not "hose barbs". I tried them because they have a larger internal diameter, however, my oil line blew off. Yep, it spewed 2 quarts of oil in a couple of seconds, and my oil pressure when to zero. Lesson learned. I replaced the smooth ends with real hose barbs. It worked, but threaded, high pressure fittings would be a better idea.

Since my temperature sender was readin low when installed with a T connector in the side of the block, I thought I better move it to the oil drain plate. This is a good idea, and if CB Performance had their act together they'd carry the VDO kit made for this purpose.

Since my temperature sender was readin low when installed with a T connector in the side of the block, I thought I better move it to the oil drain plate. This is a good idea, and if CB Performance had their act together they'd carry the VDO kit made for this purpose.